Listen up, folks. If you're in the manufacturing or machining game, you’ve probably heard the buzz around alumina cutting tools. But let's be real—what exactly makes these tools so special? Alumina cutting tools are not just another trend; they're a technological leap forward that’s transforming industries worldwide. So buckle up because we’re diving deep into why these tools are a must-have for anyone aiming for precision, durability, and efficiency.

Now, you might be thinking, "What’s so different about alumina compared to traditional cutting tools?" That’s a great question, and we’re about to break it down for you. In today’s fast-paced world, where precision is king, alumina cutting tools stand out because of their incredible hardness, thermal resistance, and ability to handle high-stress applications without flinching. It's like having a superpower in your machining toolkit.

Before we dive deeper, let’s address the elephant in the room: Why should you care? Well, if you're someone who deals with metals, ceramics, or even plastics, alumina cutting tools can make your life way easier. They’re built to last longer, perform better, and reduce downtime, which means more productivity and fewer headaches. So, whether you’re a seasoned pro or just starting out, this is one topic you don’t want to miss.

- Sage And Ivy The Ultimate Guide To Understanding Their Power And Potential

- Salt And Pepper Apparel The Trendsetting Duo You Need In Your Wardrobe

Here's a quick roadmap of what we'll cover:

- What Are Alumina Cutting Tools?

- Benefits of Alumina Cutting Tools

- Applications in Various Industries

- Comparison with Traditional Cutting Tools

- Material Composition and Manufacturing

- Maintenance Tips for Longevity

- Cost Efficiency and ROI

- Environmental Impact and Sustainability

- Future Trends and Innovations

- Conclusion: Why Alumina Cutting Tools Are Here to Stay

What Are Alumina Cutting Tools?

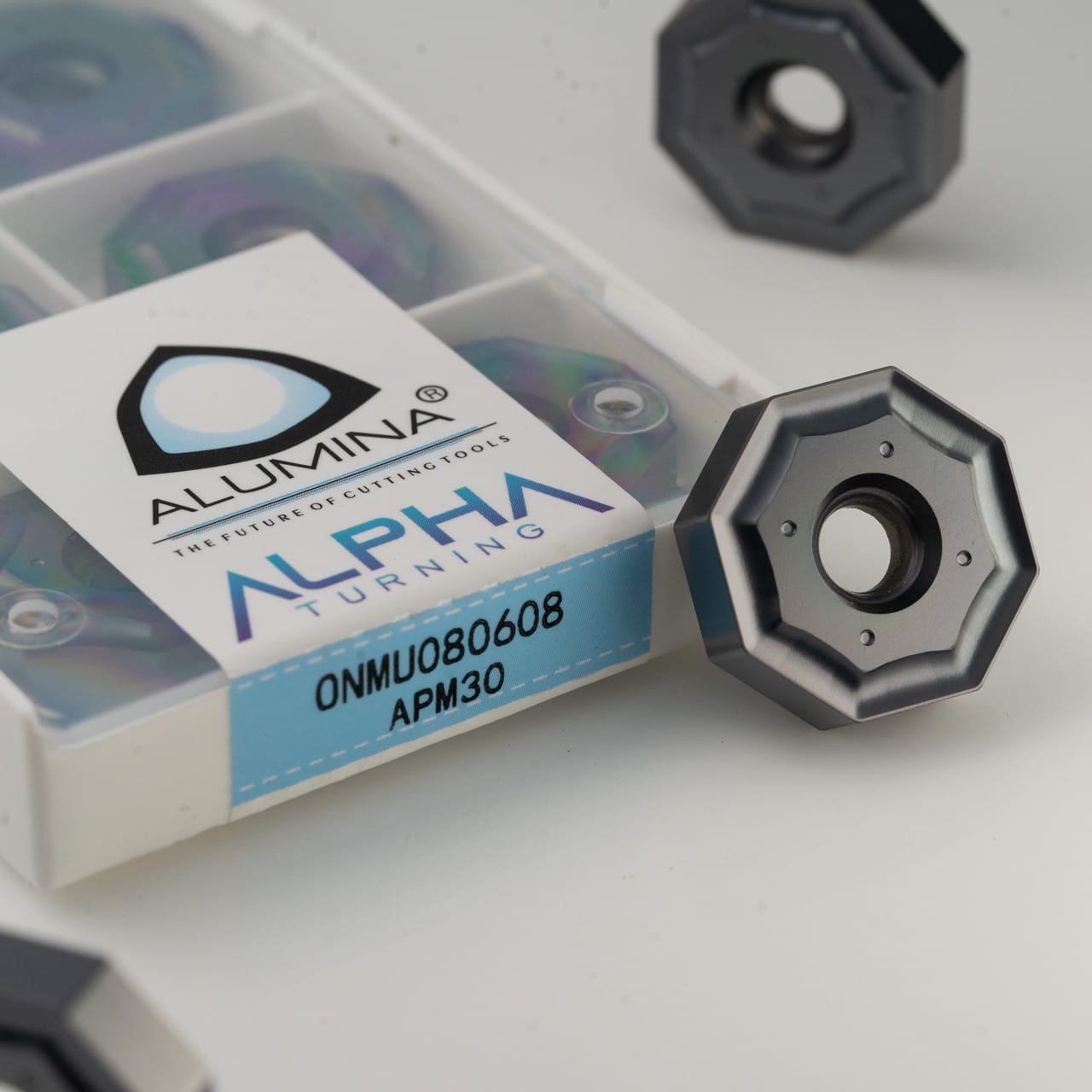

Let’s start with the basics. Alumina cutting tools are specialized cutting tools made from aluminum oxide (Al₂O₃), a material that’s renowned for its exceptional hardness and durability. These tools are engineered to handle tough machining operations with ease, making them a favorite among manufacturers worldwide.

Now, here’s the kicker: alumina isn’t just your average ceramic material. It’s got properties that make it perfect for cutting applications. For starters, it’s super hard—second only to diamond in terms of hardness. This means it can slice through materials like butter without losing its edge anytime soon. Plus, it’s resistant to heat, wear, and corrosion, which is a big deal when you’re working in high-temperature environments.

- Blackout Skate The Ultimate Guide To Mastering The Art Of Skateboarding In The Dark

- Alfredo Lopez The Inspiring Journey Of A Remarkable Individual

Why Alumina Stands Out

When it comes to cutting tools, alumina really shines because of its unique combination of properties. Here’s a quick rundown:

- Hardness: Alumina ranks high on the Mohs scale, making it ideal for cutting hard materials.

- Thermal Stability: It can withstand extreme temperatures without degrading, which is crucial for high-speed machining.

- Chemical Resistance: Alumina doesn’t react with most materials, ensuring consistent performance over time.

Benefits of Alumina Cutting Tools

Okay, so we’ve established what alumina cutting tools are, but what’s in it for you? Let’s break down the benefits:

First off, alumina tools last longer than their traditional counterparts. This means fewer replacements and less downtime for your operations. Think about it—every minute your machinery is idle is money down the drain. Alumina cutting tools help you avoid that headache.

Key Advantages

- Increased Productivity: With their ability to handle high-speed machining, alumina tools get the job done faster.

- Improved Precision: Alumina tools maintain their sharpness for longer, ensuring accurate cuts every time.

- Cost Savings: While the initial investment might be higher, the long-term savings on maintenance and replacements make it worth it.

Applications in Various Industries

Alumina cutting tools aren’t just limited to one industry—they’ve got applications across the board. From automotive to aerospace, and from electronics to medical devices, these tools are making waves everywhere.

In the automotive sector, for instance, alumina tools are used for machining engine components, ensuring precision and durability. Meanwhile, in aerospace, they’re employed for cutting advanced materials like titanium alloys, where traditional tools would fall short.

Industries That Rely on Alumina Cutting Tools

- Automotive: Engine blocks, transmission components, and more.

- Aerospace: High-strength materials like titanium and composites.

- Medical: Precision cutting for surgical instruments and implants.

Comparison with Traditional Cutting Tools

Let’s face it—traditional cutting tools have been around for a while, but they’ve got some serious drawbacks. Metals like high-speed steel (HSS) and tungsten carbide are great, but they pale in comparison to alumina in terms of performance and longevity.

For starters, traditional tools wear out faster, especially when used in high-temperature applications. They also require more frequent sharpening and replacement, which adds to your costs. Alumina cutting tools, on the other hand, maintain their edge for longer, reducing the need for maintenance.

Head-to-Head Comparison

- Durability: Alumina tools outlast traditional tools by a significant margin.

- Heat Resistance: Alumina can handle higher temperatures without compromising performance.

- Cost: While traditional tools might seem cheaper upfront, alumina tools offer better value over time.

Material Composition and Manufacturing

So, how exactly are alumina cutting tools made? The process involves a combination of science and engineering magic. First, aluminum oxide powder is mixed with binders and other additives to form a slurry. This slurry is then shaped into the desired tool form and sintered at high temperatures to achieve its final hardness.

The result? A cutting tool that’s not only hard but also highly precise and durable. The manufacturing process is what gives alumina tools their unique properties, making them stand out in the world of machining.

The Science Behind Alumina

- Sintering: The high-temperature process that gives alumina its hardness.

- Additives: Binders and other materials that enhance performance and durability.

Maintenance Tips for Longevity

Now, even the best tools need a little TLC to keep them in top shape. Here are some tips to ensure your alumina cutting tools last as long as possible:

First, always store them in a dry, clean environment. Moisture and dirt can affect their performance over time. Second, make sure to follow the manufacturer’s guidelines for usage and storage. And finally, inspect them regularly for signs of wear or damage.

Pro Tips for Alumina Tool Care

- Regular Inspections: Check for cracks or chips that could affect performance.

- Proper Storage: Keep them in a controlled environment to prevent contamination.

Cost Efficiency and ROI

Let’s talk money, shall we? While alumina cutting tools might have a higher upfront cost, they offer significant long-term savings. Think about it—fewer replacements, less downtime, and improved productivity all add up to a solid return on investment.

According to a study by the National Institute of Standards and Technology (NIST), companies that switch to advanced cutting tools like alumina see an average increase in productivity of 20-30%. That’s a game-changer for any business.

Environmental Impact and Sustainability

In today’s world, sustainability matters. Alumina cutting tools not only improve efficiency but also reduce waste. By lasting longer and requiring fewer replacements, they contribute to a more sustainable manufacturing process.

Plus, alumina is a naturally occurring material, which means it’s more environmentally friendly than some synthetic alternatives. It’s a win-win for both your business and the planet.

Future Trends and Innovations

Looking ahead, the future of alumina cutting tools is bright. Researchers are constantly exploring new ways to enhance their performance and expand their applications. From nano-engineered coatings to hybrid materials, the possibilities are endless.

One exciting development is the use of smart materials that can adapt to changing conditions in real-time. Imagine a cutting tool that adjusts its hardness and sharpness based on the material it’s cutting—pretty cool, right?

Conclusion: Why Alumina Cutting Tools Are Here to Stay

There you have it, folks. Alumina cutting tools are not just a trend—they’re a necessity for anyone serious about precision machining. With their unmatched hardness, thermal stability, and durability, they offer a level of performance that traditional tools simply can’t match.

So, what’s next? If you haven’t already, it’s time to consider making the switch to alumina cutting tools. Whether you’re in automotive, aerospace, or any other industry, these tools can help you achieve greater efficiency, reduce costs, and improve your bottom line.

And hey, don’t forget to leave a comment or share this article if you found it helpful. Let’s keep the conversation going and help others discover the power of alumina cutting tools. Thanks for reading, and stay sharp out there!

Detail Author:

- Name : Dr. Karl Cormier

- Username : uanderson

- Email : rempel.allie@yahoo.com

- Birthdate : 2001-03-31

- Address : 8004 Klein Glen Apt. 553 Mohrland, MI 58461-1655

- Phone : +1-507-361-0838

- Company : Halvorson, Cartwright and Lueilwitz

- Job : New Accounts Clerk

- Bio : Culpa in et enim qui optio sequi dolor dolorum. Doloribus voluptas iure laboriosam sit. Consequuntur ut sunt expedita sunt voluptatem aut saepe.

Socials

linkedin:

- url : https://linkedin.com/in/eichmann2006

- username : eichmann2006

- bio : Animi quas animi qui et sint tenetur hic ut.

- followers : 4557

- following : 2998

tiktok:

- url : https://tiktok.com/@mireya7894

- username : mireya7894

- bio : In rem tenetur aut eaque quia possimus. Praesentium animi sed quasi illo.

- followers : 651

- following : 2950

instagram:

- url : https://instagram.com/mireya_eichmann

- username : mireya_eichmann

- bio : Adipisci quo delectus saepe magnam debitis et. Occaecati hic laboriosam ad qui ullam vero.

- followers : 6795

- following : 2389

twitter:

- url : https://twitter.com/meichmann

- username : meichmann

- bio : Soluta eum accusamus aut iure aperiam incidunt. Mollitia nam occaecati deserunt quidem et voluptas iure. Facere culpa quod sit sunt.

- followers : 964

- following : 1546

facebook:

- url : https://facebook.com/mireya7143

- username : mireya7143

- bio : Ut pariatur recusandae sint. Nihil voluptatem porro minima commodi ipsam.

- followers : 553

- following : 237